A5 hammer production forge process

Mechanical Advantage series--sidebar

Buy the books here:

Volume 1: (mostly) European Tools and Techniques to the 1930s

Volume 2: (mostly) North American Climbing Tools and Techniques to the 1950s

As an example of how 4130 Chromoly steel goes from stock billets to production part (pitons would be similar), here are my notes from making the A5 hammer in 1986.

In the mid-1980s, there were no good big wall hammers being produced, and the rare second-hand drop-forged Chouinard Yosemite Hammers (first made in 1965, but out of production in the 1970s) or the fiberglass-handled Forrest wall hammer (which some preferred, but also sold out) would have a number of bidders in the Camp IV parking lot, going for more than the price of a couple of ropes, a hefty investment.

I don’t recall who I bought my first second-hand Chouinard Yosemite Hammer, but it was a game changer in the way it brought a bit more elegance to my developing skills of pitoncraft by being the right size and weight, and most importantly, feel, for those tricky placements where one is holding their body into a 5.9 position, and absolute precision and care is required to place a good pin (without dropping it). I went through a few Yo Hammers and often repairing tangs or replacing handles in my 1980s dozen-bigwall-a-year routine.

After getting rescued from Half Dome in May 1986, which disheartened me, and a small car accident, which bankrupted me, I left my self-sufficient life in Yosemite living on marginal funds from rescues and film work, and received some funding from my parents which I invested to make big wall climbing hammers.

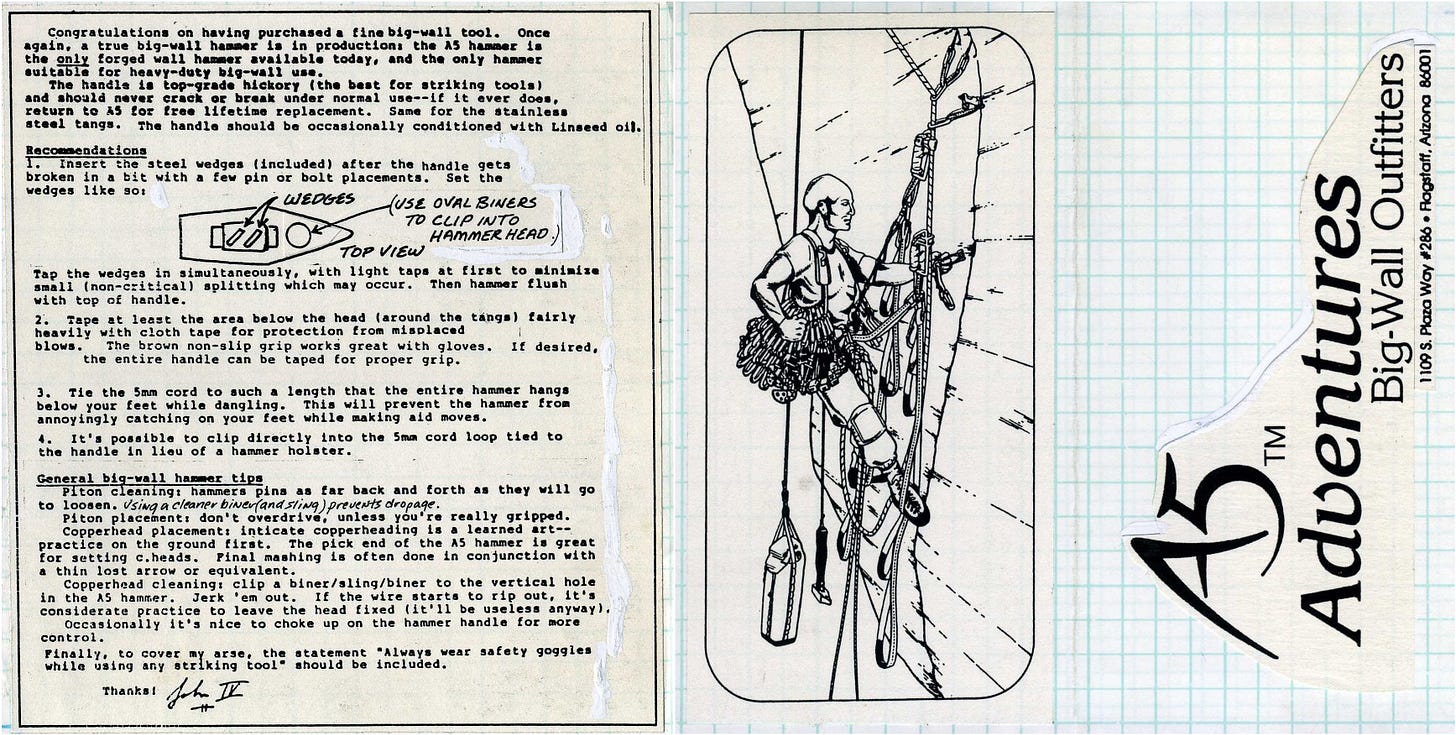

Everyone thought I was nuts. The age of pitons was over, and there would never be a market for that kind of big wall climbing gear ever again. Charles Cole had just set up 5.10, named after the classic free climbing grade, so I decided to call my business, A5 Adventures, named for the reputed top-of-the-scale aid grade. After trying to organise the business from my POB 3580 at the Yosemite Lodge, I needed an office and shop, so moved to Flagstaff, Arizona, which had great climbing and other innovators (Steve Byrne of Wired Bliss).

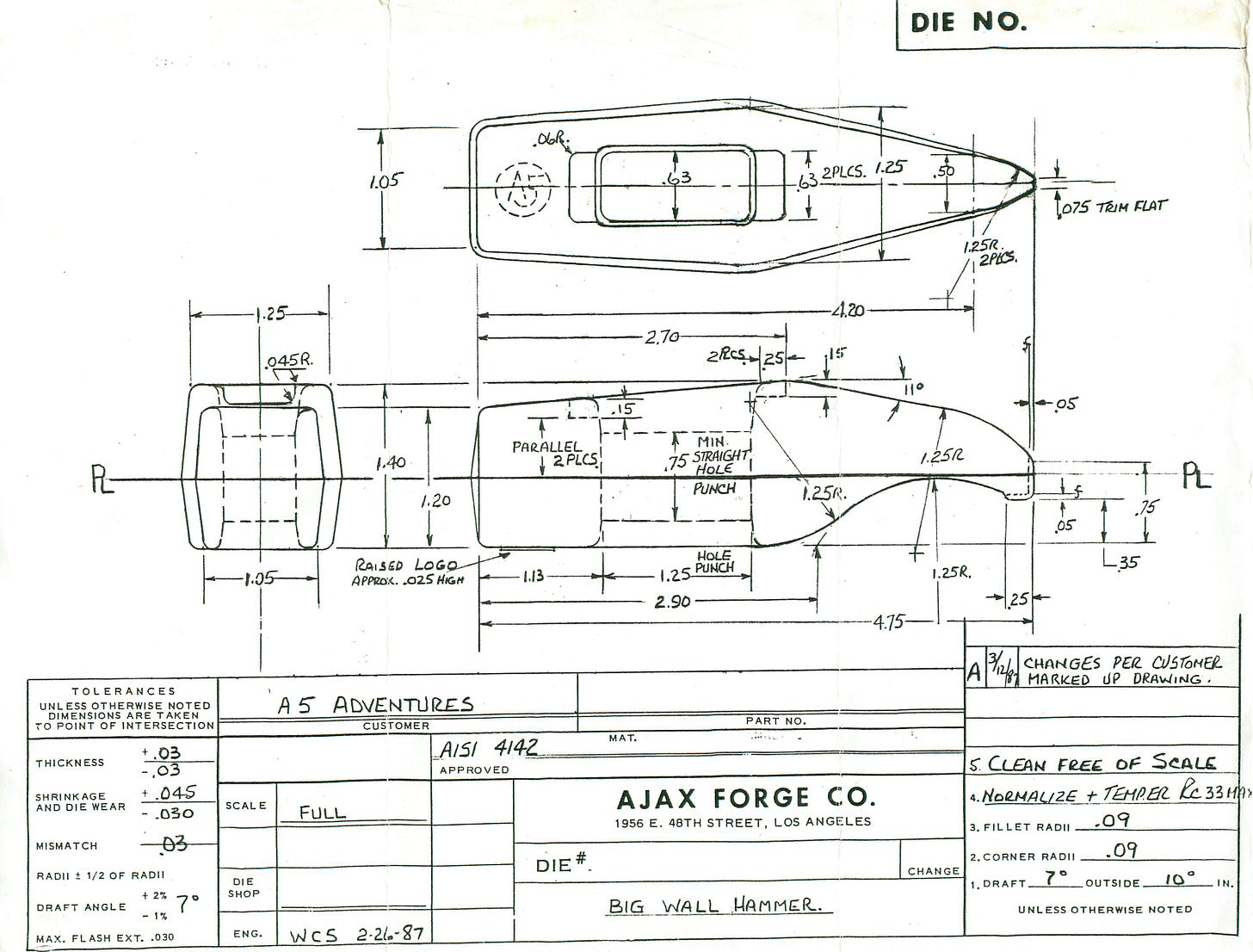

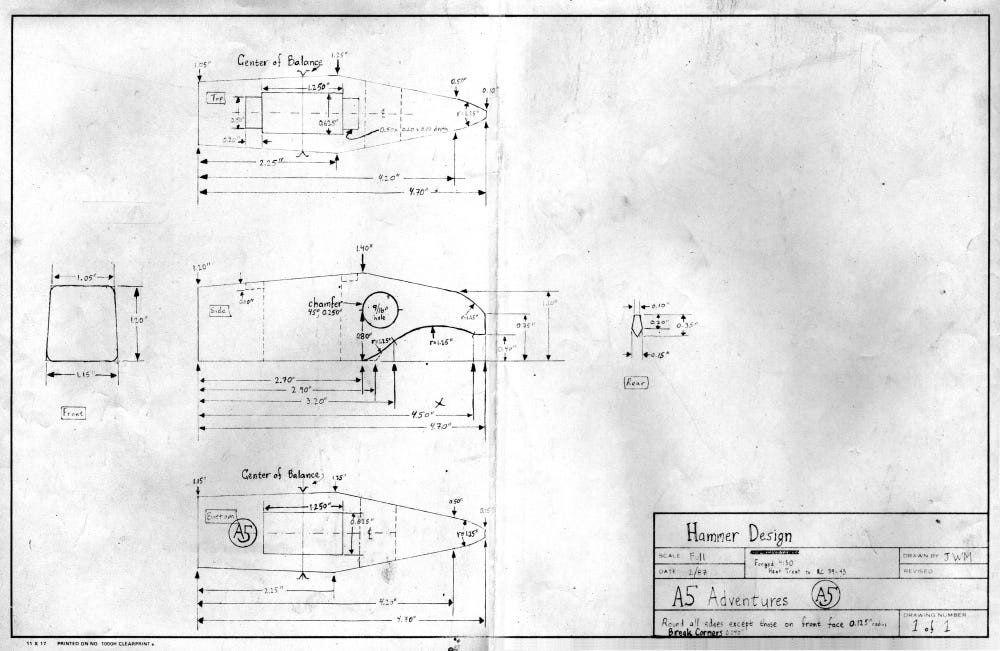

The first step in making a forged part was to go to the local Public Library and copy the contact details for companies listed in the Thomas Register, a 20-volume set of catalogs listing every manufacturer in the United States (now it is all online). Then, draw and copy a blueprint, specify material, and send this information to at least a few dozen companies listed in the Thomas Register. About eight companies would send quotes back. Some quotes were outrageously high, usually meaning the quantity wasn’t sufficient for their production schedules, and some were too low indicating that they really didn’t have the capability to produce the part as specified. Ajax forge in Lost Angeles had the best quote, and looked like the best outfit for the job. I found out 15 years later from talking to Tom Frost that Ajax Forge was also the supplier for early Chouinard forgings.

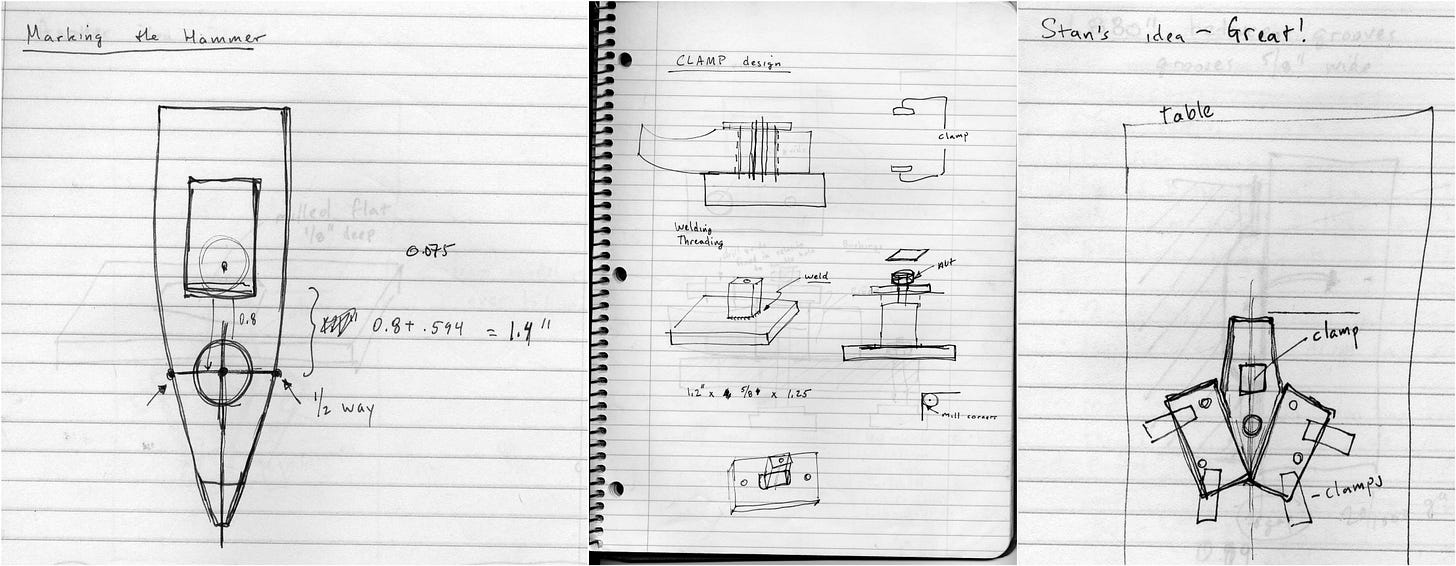

The parts would come from the forging company with a “draft” (angled surfaces so the part didn’t get stuck in the forging dies), so the front face had to be milled and a carabiner hole drilled. I bought a mill for this purpose, and donated it to Steve Byrne’s Wired Bliss shop in exchange for full use of the shop. The pick also needed to be ground on a grinder and 6” sander to optimise copperhead setting and piton removal. Basically, the A5 Hammer was a marginally improved big wall hammer, which combined the best features of the Chouinard Yosemite Hammer (with its hickory handle and tang design) and the Forrest (which had a nicer pick and also a carabiner hole). It was built to fill an important hole in the market. Because of its heft, balance, and aligned grain structure , it also became a preferred hammer for drilling bolts by hand, which was essential work in the wilderness, where motorised equipment is not allowed.

Five hundred parts is the minimum order, and with a per unit cost of $20, plus the milling machine, tang and handle production, all told, the hammers became a $20,000 project (the project had a 10% overrun, so 540 were made in the first batch). Handles came from the OP Link handle company, which at the time, were used on the best carpenter’s hammers (a lot of carpenter friends—Jim Gaun, Bob Granger plus all my desert climber friends—Stan Mish, LB, Dan Langmade, Dave Insley—knew hammers and provided insight). The trick is getting the balance and weight just right, matched to the length of the handle. So lots of little design details that you have options, but getting it right the first time is vital for a big production investment. I built wood models with woods of different densities to make adjustments.

Heat treatment

Heat treatment is where a lot of makers had got it wrong initially, and so did I. It is best to get the hammers in the fully annealed state, so they are not hard and can be machined more easily. Then the job is to get them heat treated to the desired hardness. I specified the first batch to RC42/43, a couple points harder than most pitons. But it wasn’t enough, and the first heat treat test batch of 10 or so hammers (all shipped to my friends as product testers) mushroomed fairly quick—not to make them unusable, but the edges of the face got rounded quickly (a good big wall hammer has a nice square face for hammering in corners). So for the next ones (which were going to be for sale), I specified RC45/46, which seemed to be a sweet spot for a 4130 Chromoly steel big wall hammer (my second batch of 250 A5 hammers a decade later, I went with 4340 and specified to about RC48, which was more similar to the BD investment cast hammer, but I prefer the “softness” of the first batch personally).

Fantastic history of the big wall hammer!

Duecey, This article hits home for me in a lot of ways. Starting Kahtoola (with you as an early advisor) included several similar sketches for the KTS crampons and even using some of the same vendors (Jorgensen, Phx heat treat). That was back in 1998 or so. Thanks for the inspiration and I hope to catch you in Flagstaff sometime! Danny Gio.