Climbing Pitons Early Evolution--part 1d--Inline pitons and the rise of steel

Mechanical Advantage #8d

Buy the books here:

Volume 1: (mostly) European Tools and Techniques to the 1930s

Volume 2: (mostly) North American Climbing Tools and Techniques to the 1950s

Early ring pitons and the inline-eye piton design

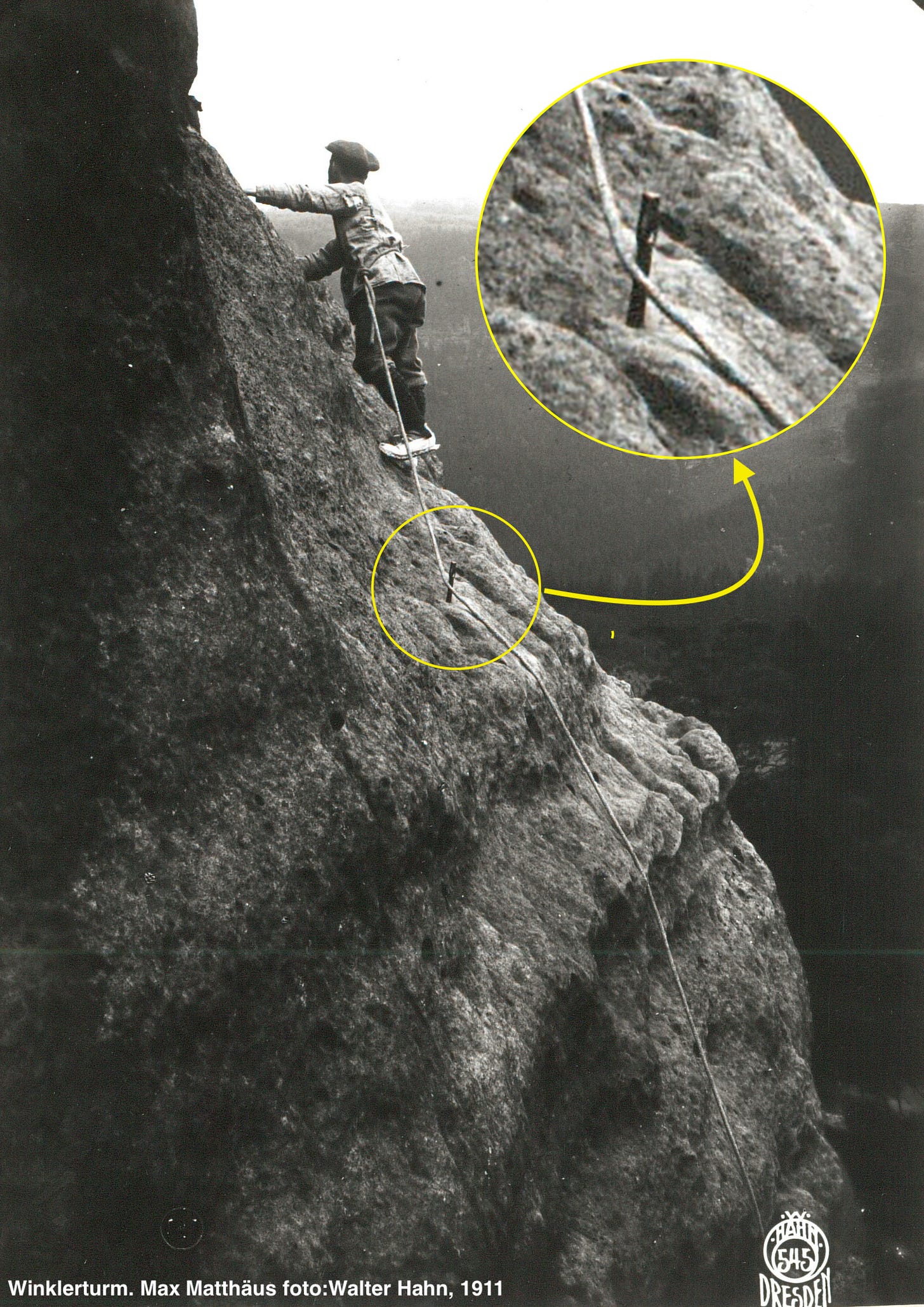

Evolving from eyebolts, such as the type George Anderson used on Half Dome, and would have been a common rock anchoring tool during the industrial era, pitons with rings appear.

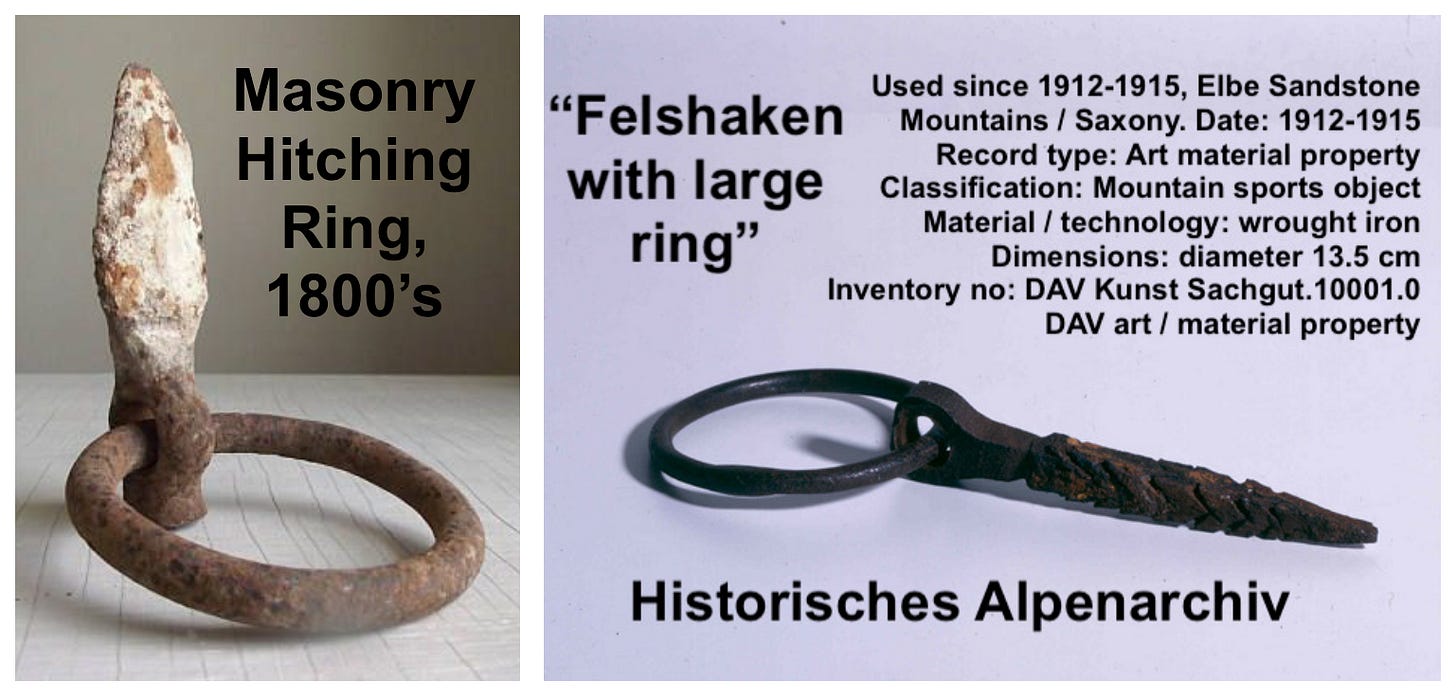

Even though there were many designs of masonry wall hooks with rings for hanging items on walls, perhaps tying up a horse, most of these early tools with rings would not have been strong enough for climbing applications. Forge-welding rings with hammer and anvil is a laborious process, and there is little evidence of any wrought iron pitons that were custom made for climbing with a forged ring, as the technique of tying off a fixed piece of protection with a short loop of rope was the standard practice of the day, when dynamic lead falls was not an option, and a low-friction ring was not required.

Ringhaken (‘Ring hooks’) as a climbing tool appears in the 1909 Nieberl, “Das Klettern im Fels” (which, by the way, is an excellent resource for studying climbing gear evolution, as there were a number of updated editions every decade into the 1950’s), as well as in a series of illustrations by Carl Moos. Most of these pitons are identical to tools used by loggers to lash log rafts together. The rings appear spot-welded, rather than forge-welded, so would have likely been made in a factory rather than a local blacksmith’s shop.

Notwithstanding the known use of pitons with an integrated rings in the early piton era, the term “Ringhaken” does not appear frequently in the old German-Austrian journals. There is a mention in 1905 (“to drive wall hook with ring so firmly, the rope is pulled through, we can finally calm down”) and in 1910 as a point of abseil on the Breche du Perron traverse by O. Meyer. Pitons with a ring were primarily intended as rappel anchor pitons. More options of thickness and lengths of ring pitons appear in the years before WWI and then more frequently in the 1920’s and 1930’s when Sporthaus Schuster began selling ringed flat pitons, but soon after the term fades from the German-Austrian records as most piton types just become known in the literature as generic “Haken” (or “Felshaken”—rock hook). Ring pitons—a ring on a flat blade of varying lengths and thicknesses—become more common in the 1920’s as protection pitons with stronger steels and more local welding shops.

The early journals have frequent references related to “Haken mit Seilring” (hook with rope ring)—but these are not ring pitons—a Seilring (rope ring) is actually a piece of cord, tied or looped around the piton and the rope, and often used as an aider for pulling on and also stepping into—sometimes referred wryly as a “noose” as climbers bypassed a section “von Seilring zu Seilring” (aiding up a line of fixed gear—modern climbers call it a ‘cluster**k’ when tangled in webbing and rope). Eisenrings—separate iron rings that were readily available as a stock hardware item—were primarily used for descent and will be covered in a future abseil tools and technique article. In the era before carabiners, straight pitons with a larger eye, similar design of non-ringed log dogs of the era, that would allow a thick short cord to be easily passed through the eye were more likely the preferred piton. Pitons with a large inline eye first appear in the Elbsandsteingebirge as bolts (Elbe advancements will be covered in a separate post on early free-climbing tools and techniques).

Rather than ring pitons, the evolutionary link between the original Mauerhaken and the modern piton is perhaps closer related to the long piton design with a large inline eye. These might have originally been loggers’ tools and modified to become the early bolts used in the Elbsandgebirge, or flattened by a smith to become a thin piton. This design would have been a more versatile and safer wrought iron or steel piton in the pre-carabiner days when Seilrings were the standard method of attachment, compared to a ring piton with a connected eye of unknown strength. Only a few examples of old inline eye pitons appear in museums, of note is an interesting piton of unknown origin in the Italian National Museum:

Carabiner evolution will be a separate study in this series, but the oft-cited idea that the piton/carabiner synergy begins in 1910 is a bit more nuanced—carabiners as a specific climbing/mountaineering tool date back to at least 1898—but it was rare for a climbing team to have more than three carabiners, mostly used for specific body-weight tasks, even well into the 1920’s. Cords were the primary means of connection, and designers of the era discuss smoothing and rounding of the piton eye well to ensure there are no sharp edges to damage the attachment cord (more on the early designers and breakthroughs using carabiners and other gear innovations later, of course).

Regardless of method of attachment, what was really missing in the early 1900’s was a thin piton that would be strong and light. A flattened wrought iron spike would have been weak and tend to shear. Fortunate for those exploring the wild vertical — often in thin brittle cracks of fractured limestone and dolomite that would shatter if hammered with a round spike—the broader availability of sheet steel coincides with this early era of technical rock climbing.

The Rise of Steel

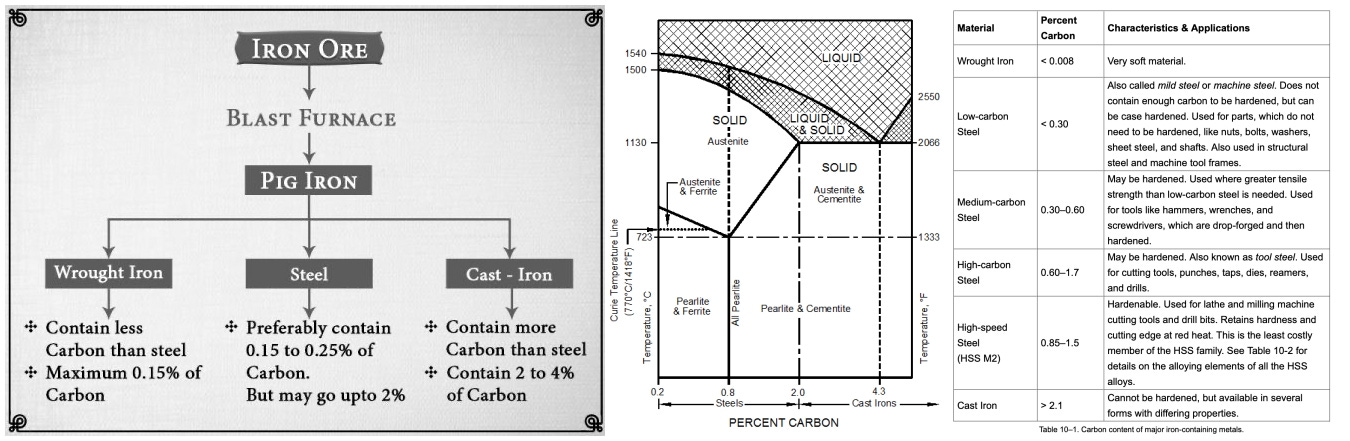

With the advent of cheap, hardenable steel by the early 1900’s, pitons really came to fore as a useful climbing tool that allowed new standards of human endeavor on the vertical to be expanded. Most, if not all pitons used for climbing before 1900 were made of wrought iron, rather than steel, and were rather thick and heavy affairs; a lighter, stronger, and thinner piton was the next step in gear evolution. For the puposes of studying early pitons, three types of iron products need to be understood:

Wrought iron: very low carbon steel, most common form in mid-1800's, and the standard blacksmith’s material. Not heat treatable but can be case-hardened. Soft: thin sections would be unsuitable in the context of a hammered piton.

Mild Steel: low carbon, heat treatable. Available in sheet form by the 1900’s.

Cast Iron: iron with high carbon--very brittle and shatters when hammered. Used for ornamental or pure compressive structural applications.

Steel goes back to the earliest times of the “Iron Age” (and likely before, from meteorites), though the science of iron additives was more based on often secret processes rather than an understanding of chemical elements. The smelting and forging process of Japanese maraging steels—known for both strength and toughness—used to make swords a thousand years ago is still not fully understood from a materials science standpoint, for example. The history of iron and steel is the story of western civilisation; new mines were a major incentive of the Roman’s expansion, and the story of European power shifts and America’s rise in the 1900’s align with the rise of steel and energy technology and production.

Before the invention of the Bessemer and Siemens steel mass-manufacturing methods in the mid 1800’s, most steel was made in a crucible in very small quantities ~50kg at a time; thus steel was expensive and only used for specialist applications, with the UK, Sweden and Russia being the largest producers (in areas with large forests). In 1850, with charcoal as the main fuel source and global deforestation reaching a peak, output was measured in tens of thousand of tons per year: Britain, the world’s largest steel producer, was making 50,000 tons of steel per year.

By 1900, steel was made primarily with coal and output was measured in millions of tons per year: Germany, the world’s second largest producer (after the US), was making 4m tons of Bessemer steel and 1.5m tons of Siemens steel per year. Wrought iron supply, largely from Sweden, dwindled to negligible quantities. Wrought iron feats of human engineering like the Eiffel Tower were superseded by steel high-rises and engineering marvels like the Brooklyn Bridge in New York and the cantilevered Forth Bridge in Scotland. The Iron Age had given way to the Steel Age.

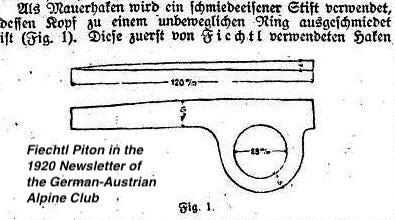

Inexpensive sheet steel, strengthened by the rolling process, would have become widespread in the early 1900’s. A reference to a steel piton (“Prima-Stahlhaken”) appears in a 1907 journal. The earliest reference to Fiechtl pitons appears in the 1920 Mitteilungen des Deutschen und Österreichischen Alpenvereins and based on the design and specification, these pitons are most likely cut to rough shape from sheet steel, rather than originating from a billet, then the taper and eye punched using forging techniques. Steel horizontals also appear in the early 1920’s, the process for making these will be covered in the next chapter.

There are many early pitons of unknown origin in climbing museums around the world; with metallurgical knowledge, such early pitons could be better identified with a hardness tester and by examining the grain structure of the steel using a file, an acid surface treatment, and a magnifying lens in order to identify the composition and approximate era of the manufacturing process of the early steel pitons.

—Next post will cover Fiechtl design(s) and other early piton innovators. Onto part 1e.

Then, Climbing Pitons Early Evolution—part 2—will cover how these mountaineering specific tools advanced the level of climbing leading to co-evolution of gear and techniques. Please leave a comment and subscribe if you are enjoying this series. This post will likely get updated as more information arrives from various sources.

LINKS

In the Beginning: Subtle Means and Engines

The Modern Era of Mountaineering (1786)

American Trail Builders, 1800's

Rope Technology in the 19th century

Mizzi Langer -- first advertised rock climbing pitons (Mauerhaken)

Climbing Pitons Early Evolution--part 1a

Climbing Pitons Early Evolution--part 1b

Climbing Pitons Early Evolution--part 1c

Climbing Pitons Early Evolution--part 1d

Climbing Pitons Early Evolution-part 1e

Tita Piaz-Alpinisto Acrobatico (Piaz PartA)