Climbing Pitons Early Evolution-part 1e--Fiechtlhaken Design.

Mechanical Advantage #8e

Buy the books here:

Volume 1: (mostly) European Tools and Techniques to the 1930s

Volume 2: (mostly) North American Climbing Tools and Techniques to the 1950s

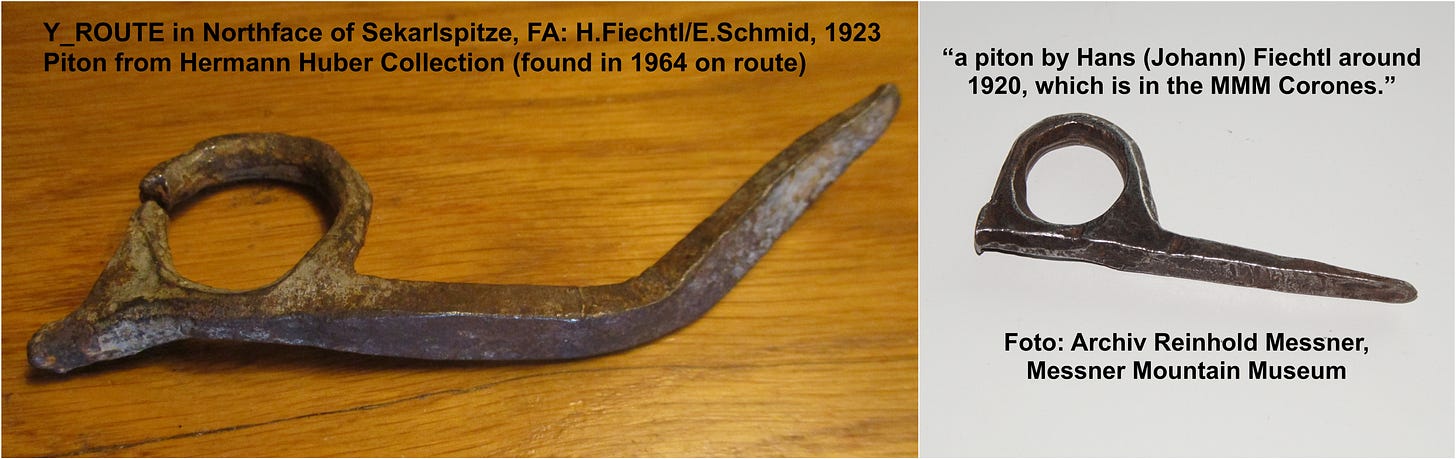

Fiechtlhaken—the first modern piton c.1905-1910

Hans Fiechtl is credited with the first thin piton design with a larger offset-eye, the core design element of the modern piton. The eye—if nailed to the hilt—provides extra support in vertical cracks, and the offset design reduces ovaling of the round eye when getting pounded, thanks to continuous material through the centerline. Limestone cracks are hard and brittle, but also can be very undulating, so the proper hardness of the piton—not too soft, but not too hard—enables the piton to weave deep into tricky placements without shattering the rock. Fiechtl and his blacksmith figured out the optimal hardness for a good limestone piton, and shared the new design widely (footnote1).

Reading the German-Austrian Alpine Club journals, there was an increase in piton climbs—all considered “artificial aid” ascents—at the turn of the century and booming by 1910/1911, so it’s likely that some climbers had access to versatile and lightweight pitons that could be quickly tied off safely earlier than 1910 (footnote2). Oskar Schuster was one of the best all-around rock, ice, and expedition climbers of the era and describes placing pitons (and bolts) “of many sizes” on tricky leads. Tita Piaz, one of the great free climbers of the period, used pitons efficiently and effectively for rock climbing belays and protection, and mastered the use of a specialised piton hammer for faster and safer rock climbs up the steepest terrain (footnote3).

Footnote1: according to journalist and alpinist, Horst Höfler, Fiechtl’s early pitons were made in Münster, where he lived at the time, by blacksmith Mühlbacher. Perhaps family: blacksmith Anton Milpacher (now Mühlbacher) was built Anthony Chapel in the neighbouring town of Jenbach in 1719, and today in Münster, one of the larger engineering firms there is called Mühlbacher. The date of the first Fiechtlhaken made by Mühlbacher is unclear, but there is a reference that Fiechtl might have still been using traditional wrought iron Mauerhaken on the Rofanspitze in 1908. Münster is in the valley between the Karwendel and Wilder Kaiser ranges, where technical big wall rock climbing begins (and will be topic of future post and cover the early pioneers). Note also that Fiechtl’s name is often misspelled as Fichtl in the literature.

Footnote2: Mitteilungen des Deutschen und Österreichischen Alpenvereins (1875-1938) and Zeitschrift des Deutschen und Österreichischen Alpenvereins (1870-1940). Best search engine here.

Footnote3: in the famous Mauerhakenstreit debates of 1911-12, Georg Leuchs commented on how Piaz was willing to use up to 30 pitons for an ascent, as reported by Hans Dülfer; the context for this will be explained in a future article on Tita Piaz’s amazing climbing career.

The greater availability of stronger hardenable steels required blacksmiths to broaden their skills, as industrial mass production reduced demand for locally smithed metalware. Heat treating metal at the time was an evolving science, and new tools required varied hardnesses now possible with various new steels. It is not so much as the prior wrought iron material used for pitons was weak, but that wrought iron is not hard—and not able to be hardened by heat treatment—there is not enough carbon in wrought iron to create a harder steel for effective bashing into cracks. Perhaps it’s better to say, “steel heat treatment is an art” (heating/quenching/tempering) during this period in order to optimize hardness and elongation for a specific application. And new thin steel pitons were needed to protect the bold new climbs being accomplished in this era.

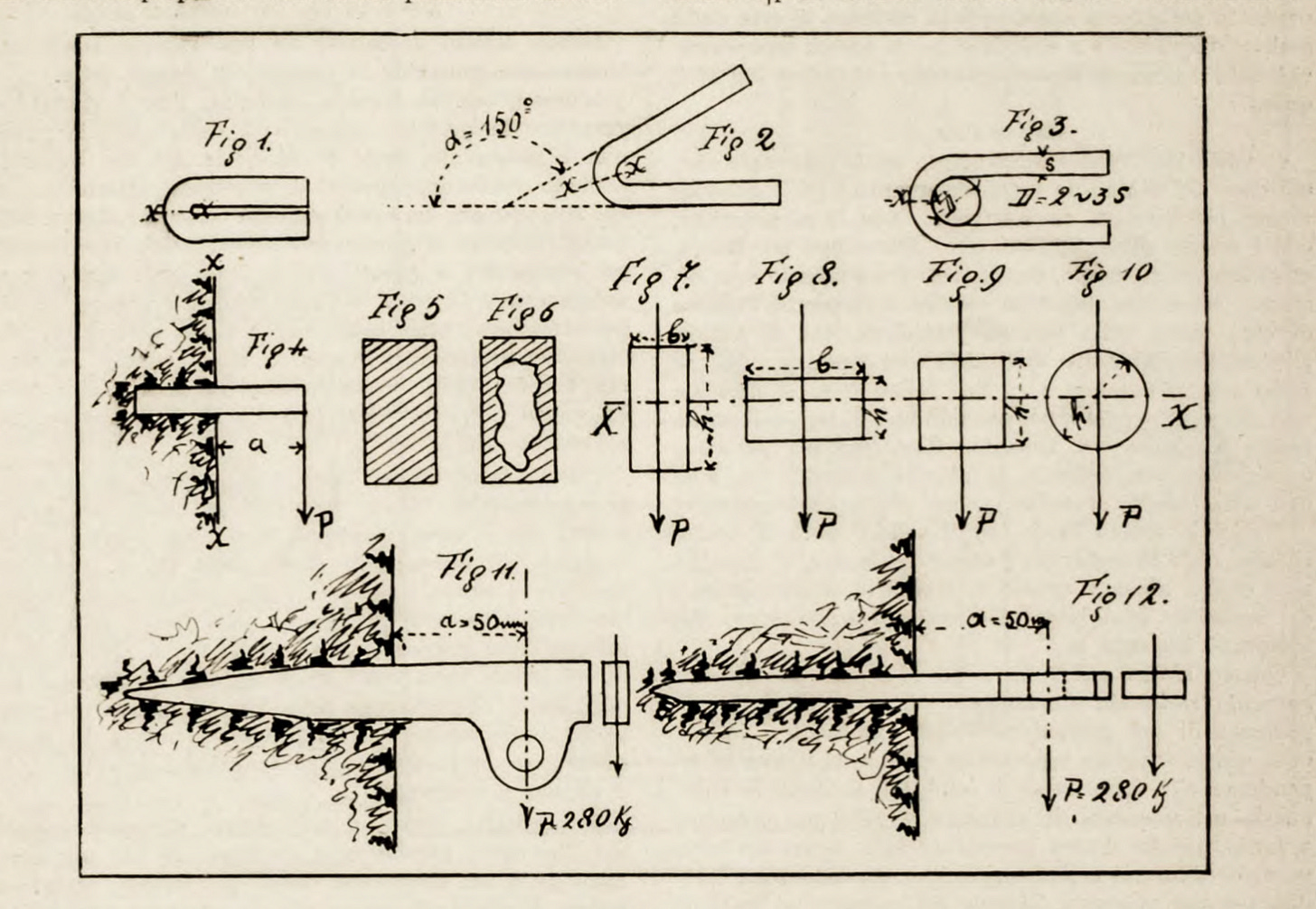

Awareness of better protection systems increased as pitoncraft knowledge was shared more widely. The 1920 Mittielungen article “Das Versichern beim Klettern” (Security for Climbing) is an overview of a basic protection system using rope, piton, carabiners and rope slings, and is the first published reference to Fiechtl’s original piton design. The article was written in response to a “sad accident” witnessed by the author when the second was killed after the leader fell, taking both to the air, and mentions that those “who find pleasure in danger” is fine, but only if going solo, and optimising security—especially a belay— for a team is justified for those who care about life (footnote4). In the pre-WWI period, there were some who had developed good protection technique with pitons, and many who did not either out of principle or lack of access to the new tools, but the teams that adopted the new protection devices put up some incredible big walls.

Note that even in 1921, a reference to a “Stahlhaken mit Seilring” (steel piton with rope ring) indicates that a rope sling (1m length of 5-7mm cord) was still a standard connection system, as only a few carabiners were carried by most climbers at the time—primarily saved for rope manoeuvres—steel carabiners were still rare and probably quite expensive (footnote5). Designers stressed the importance of rounding the inside of the piton’s eye so as not to leave a sharp edge that could cut the rope ring (1926).

The original Fiechtl design has stood the test of time, and was a primary piton design well into the 1960’s and even today with some specialty pitons from other metals (titanium versions can be bought today).

Footnote4: The author of the 1920 article describes a “wrought iron (sic) pin used as a wall hook, whose head is forged into a fixed ring, and combine all the advantages of strength, suppleness, and equity”; but often, even by climbers and authors into the 1930’s, steel is mistakenly referred to as iron. Wrought iron has a hardness ~100 Brinell, I recently tested a mild steel Army piton (photo) around RC15, ~200 Brinnell, and early mild steels at the time would have been similar hardness. Modern 4130 chromemoly knifeblades are RC41/42, equivalent to Brinell ~375. The best early Fiechtlhaken were crafted from flat plate steel stock of the appropriate thickness, simplifying manufacture for eye and taper.

Footnote 5: also to note that from from 1914-1922, the region was beset by war (1914-1918), flu pandemic (1918-1920), and hyper-inflation (1921-1922) in succession, so it’s amazing there was any development and production of “high tourist” needs during this period, let alone the incredible innovation in rock climbing tools and techniques.

SIDEBAR—FORGING PITONS by Mitchell Goldman, full time blacksmith writes:

If the first steel Fiechtl pitons were cut from flat bar-stock steel and then finished by hand, which seems likely, it would be very easy for even a modestly skilled blacksmith to “set down” the steel in such a way as to make it suitable for a horizontal placement. You would hold the blade of the piton over the face of the anvil with the eye of the piton pushed against the side of the anvil face and with repeated blows, set down the material with the hammer, moving the profile of the steel to be less tall and more wide.

As for making 1” holes for the eye in sheet steel, a stud punch or slot punch is used, then the eye is drifted to the desired shape and size using one (or a series of progressively larger) tapered tools called a Drift. By punching and using drifts, “stretch” the hole to desired size. If one wanted the hole to swell below the centerline of the stock, like the eye of a piton, maintaining a straight top line, you would just make the hole offset toward the side of the stock meant to be the bottom of the piton.

Horizontal Fiechtlhaken

Necessity breeds invention, and sometime before 1922, horizontal pitons also appear, with the blade at right angles to the eye (the design generally known as “Lost Arrows” in Yosemite). Flat Fiechtlhaken are good in vertical cracks, but poorly loaded in horizontal cracks. Horizontal Fiechtlhaken are more versatile as they work for both vertical and horizontal cracks, as the added torque on the blade when loaded in vertical cracks is often beneficial to its holding power. Early pitons were custom made by various blacksmiths, and there are reports of bad ones with the smiths outed in journals (on the Durreck, 1910: “The first wall hook—from the blacksmith in Sand—bends. Only the second ‘real’ one holds”).

Larger cracks were sometimes protected with wood wedges until the invention of angle pitons with new materials and manufacturing techniques in the 1940’s. It should be remembered that the best climbers of the early 20th century were exceptional lieback, off-width and chimney maestros and maestras, even by today’s standards (practice for these techniques are rarely found in today’s climbing gyms), and boldly “ran it out” on larger cracks and desperate chimneys, at a time when anything longer than a 3m fall on the ropes of the day was a dice roll. Pitons were generally carried in coat pockets, and tales and tips were shared on awkward tricky placements runout on lead, placing a good anchor with one hand deftly .

Flat pitons with welded rings were also produced in various sizes in the 1920’s and beyond, but considered less versatile—less safe in horizontal cracks due to awkward loading of the ring—and were best employed as rappel anchors. Long serrated Fiechtlhaken were also used as ice pitons. Flat and horizontal pitons with the offset eye were the two main designs for the next several decades, and both designs have ever since been referred to as Fiechtlhaken, with many variations of the blade. Sometime in the 1920’s ASMÜ Schuster began mass producing (footnote) flat and horizontal pitons with blacksmiths in Bad Oberdorf (Allgäu mountains), and the ASMÜ pitons were shipped worldwide, finding their way into mountain ranges all over the world.

footnote: Hermann Huber clarifies: “After having seen the workshops of their makers in Bad Oberdorf, I can only say it was not a real industrial mass production, but they must have been quite busy in following the market demand. The ASMÜ pitons were more or less monopolic in Germany for a while.”

The images below help tell the early Fiechtlhaken story:

This finishes the series on early piton development. Next, we’ll cover how these and other new tools advanced with key milestone climbs and leading to further co-evolution of gear and techniques in Tyrol and Italy. Carabiner history will also be covered. Please leave a comment and subscribe if you are enjoying this series (and if you have any details to add!).

LINKS

In the Beginning: Subtle Means and Engines

The Modern Era of Mountaineering (1786)

American Trail Builders, 1800's

Rope Technology in the 19th century

Mizzi Langer -- first advertised rock climbing pitons (Mauerhaken)

Climbing Pitons Early Evolution--part 1a

Climbing Pitons Early Evolution--part 1b

Climbing Pitons Early Evolution--part 1c

Climbing Pitons Early Evolution--part 1d

Climbing Pitons Early Evolution-part 1e

Tita Piaz-Alpinisto Acrobatico (Piaz PartA)

Just to clarify, there is no evidence that Hans Fiechtl was a blacksmith, as frequently seen in history books on climbing (such as The Brilliant Outsider, by Robert Wainwright, an excellent book on George Finch). There is more evidence that he worked with a blacksmith as mentioned above, based on his design (actually, it is not entirely clear he was the original designer, but he was probably the first producer of batches of pitons that he shared or perhaps even sold).

Great stuff! Especially the early metallurgy and machining!